hotend upgrade

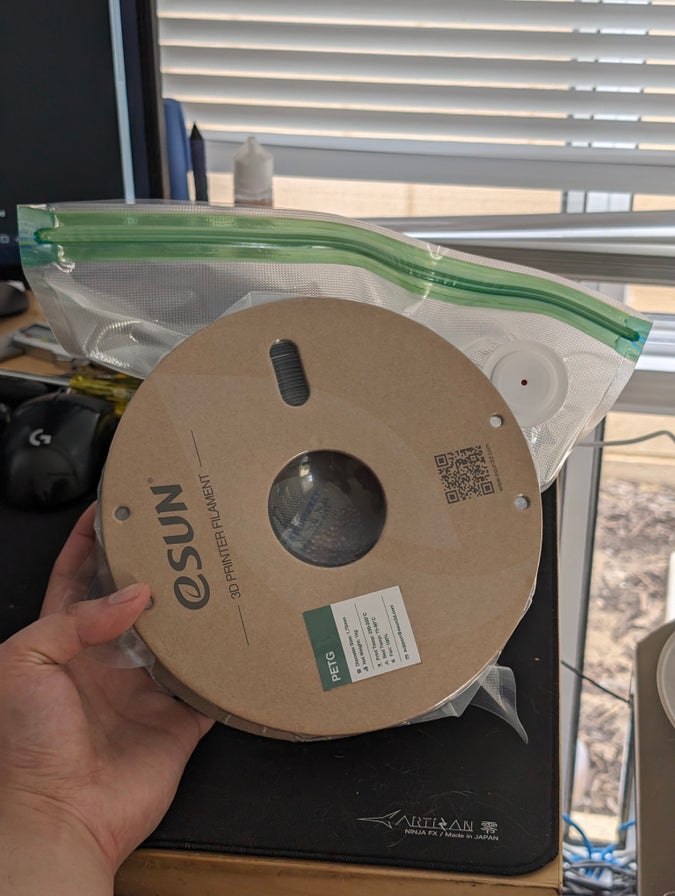

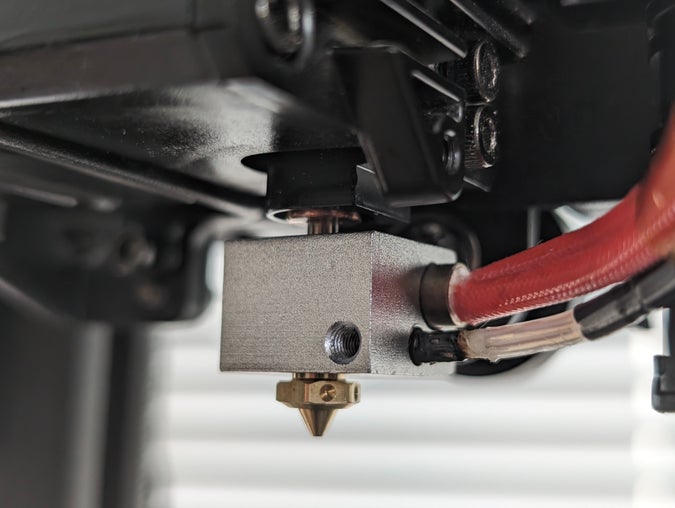

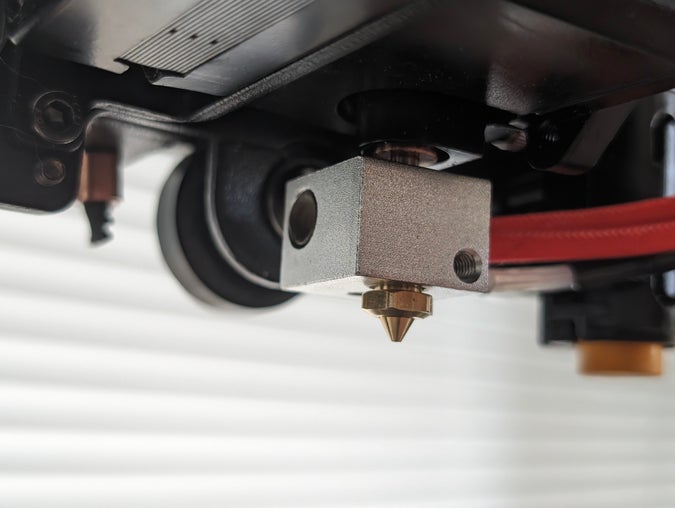

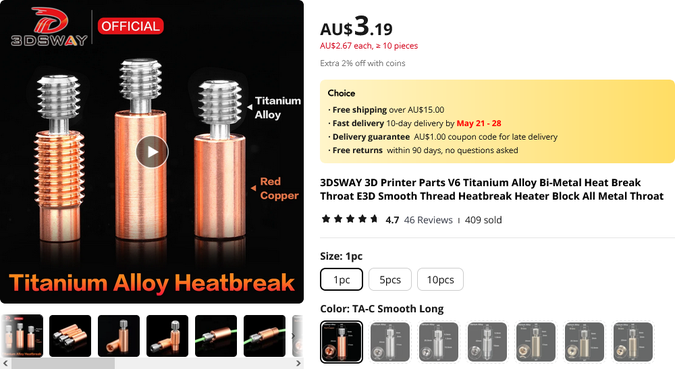

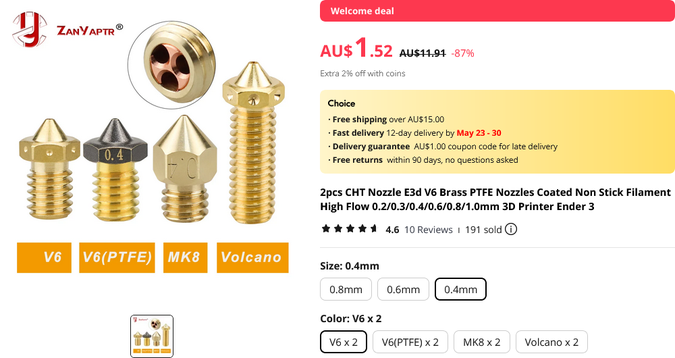

@ariashark and i upgraded the kobra neo’s hotend to use an all-metal heatbreak and high-flow nozzle, which will hopefully allow us to print petg properly.

this took like a month and a few false starts, first because we needed tools (16mm spanner and 1.5 Nm torque wrench), then because the threads on the heatblock and nozzle were fucked (ty anycubic), then because the heatblock we bought locally was for a smaller thermistor (and had no grub screw, which seemed kinda sketchy). but we made it!